Techno Springs India has provided customers with custom precision springs since 1978. We manufacture springs for variety of industries including automotive , electrical , agriculture machinery, railways and construction machinery.

It has a modern plant with a covered area of 80,000 sq. ft. with latest world class manufacturing & testing facilities. Our Quality System is approved to ISO/TS16949:2009. Every step of the manufacturing process is carefully monitored.Tolerances and specifications are inspected utilizing the most advance equipment available today.

With trained management and workforce who have gained extensive product knowledge through team experience, we seek to be your production partner for springs, wire forms and assemblies.

Techno Spring exports to customers in North America & Europe, as second tier supplier to all the major automotive OEM's.

Vision

Techno Springs India goal is to exceed your expectations in quality, service and reliability.

Mission

Techno Springs India is committed to the high standards established over the last 35 years and to continuously improve upon them by using state-of-the-art equipment and the very latest in quality techniques and procedures.

Your reliable source for

Springs

| Automotive 4W | Automotive 2W | Commercial Vehicle | Railway Brake System | Electrical & Switchgear | Agriculture Tractors & Machine | Construction Machinery |

| Door Checkers & Hinges | 2W Switches | Brake System | DV Brakes | Motors | Transmission | Transmission |

| Brake Actuation System | 2W Brake Application | Transmission | Brake Cylinder | Starters | Breakes | Breakes |

| Fuel Injection System | 2W Body Parts | Steering & Suspension | BMBS | Contractors & Relays | Body Parts | Body Parts |

| Steerin Suspension & System | Carburetors | MCCB | Rotavator | Cabin | ||

| Seating Mechanism | MPFI | AC Brakers | ||||

| Fuel Indication System | Limit Switches | |||||

| Door Trims |

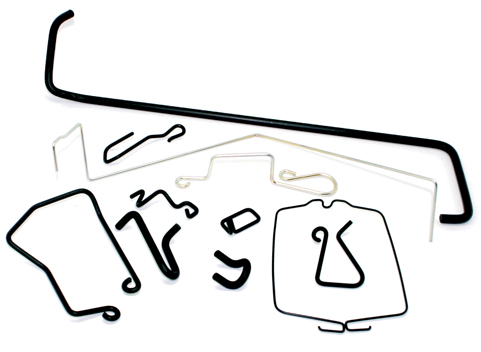

Bending wires in

any shape

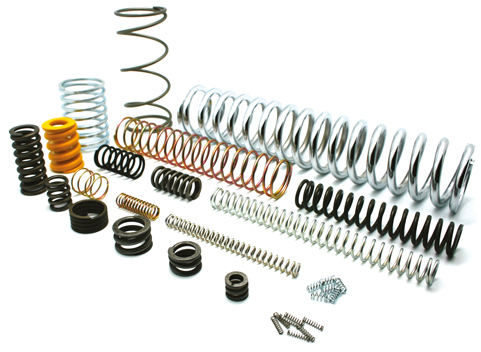

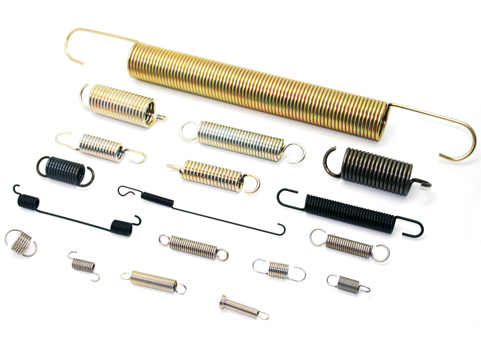

As per customer specifications, we can produce springs in variety of shapes & materials. Our capabilities range from 0.10mm to 11mm diameter wire springs of following types: compression, extension, torsion, double torsion, conical, spiral, elliptical springs, flatform & wireforms. The company is fully equipped to achieve a variety of surface treatments & specialized heat treatment requirements.

Conical Springs

Conical Springs

Torsion Springs

Torsion Springs

Wire Form

Wire FormLatest world class manufacturing facility from

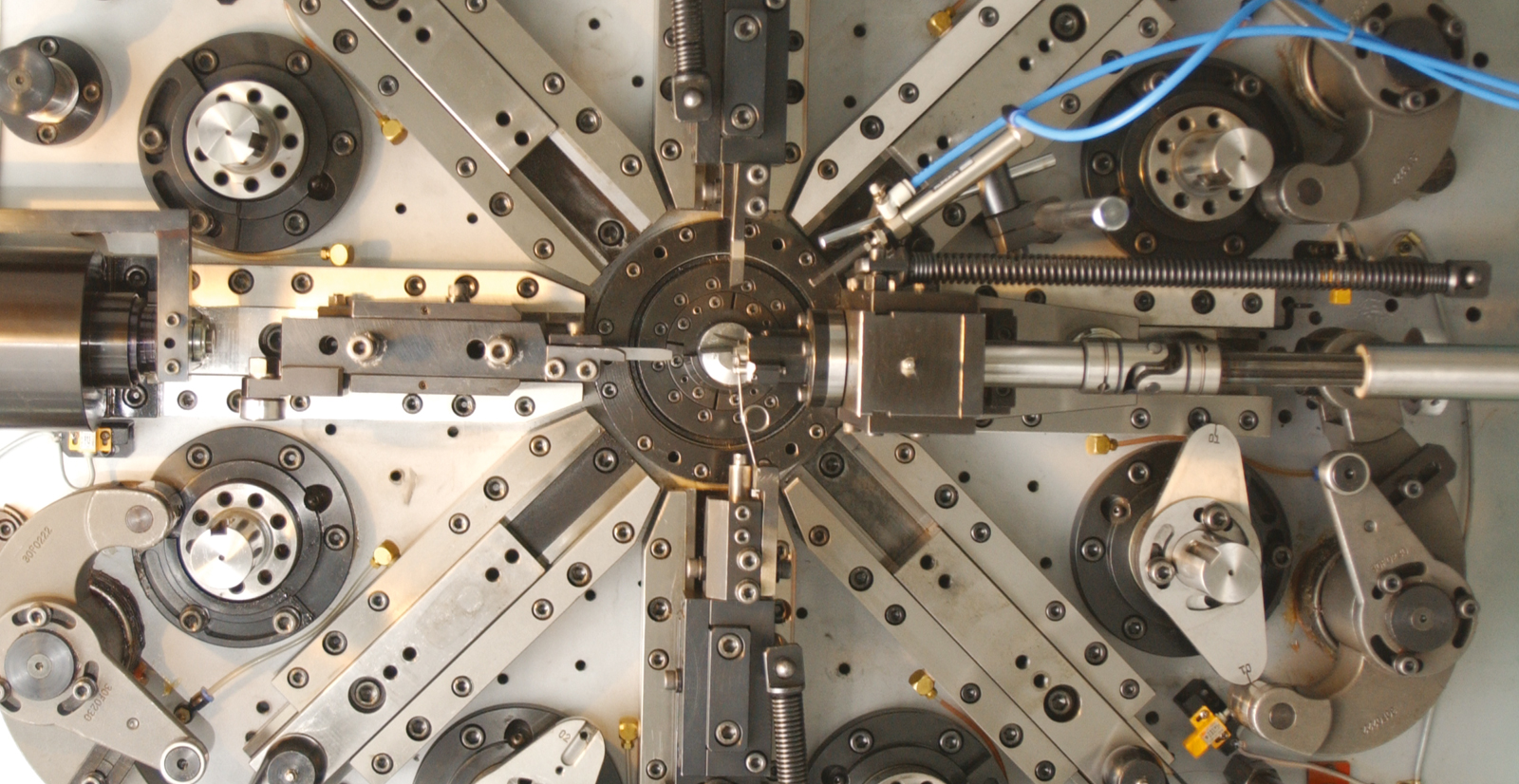

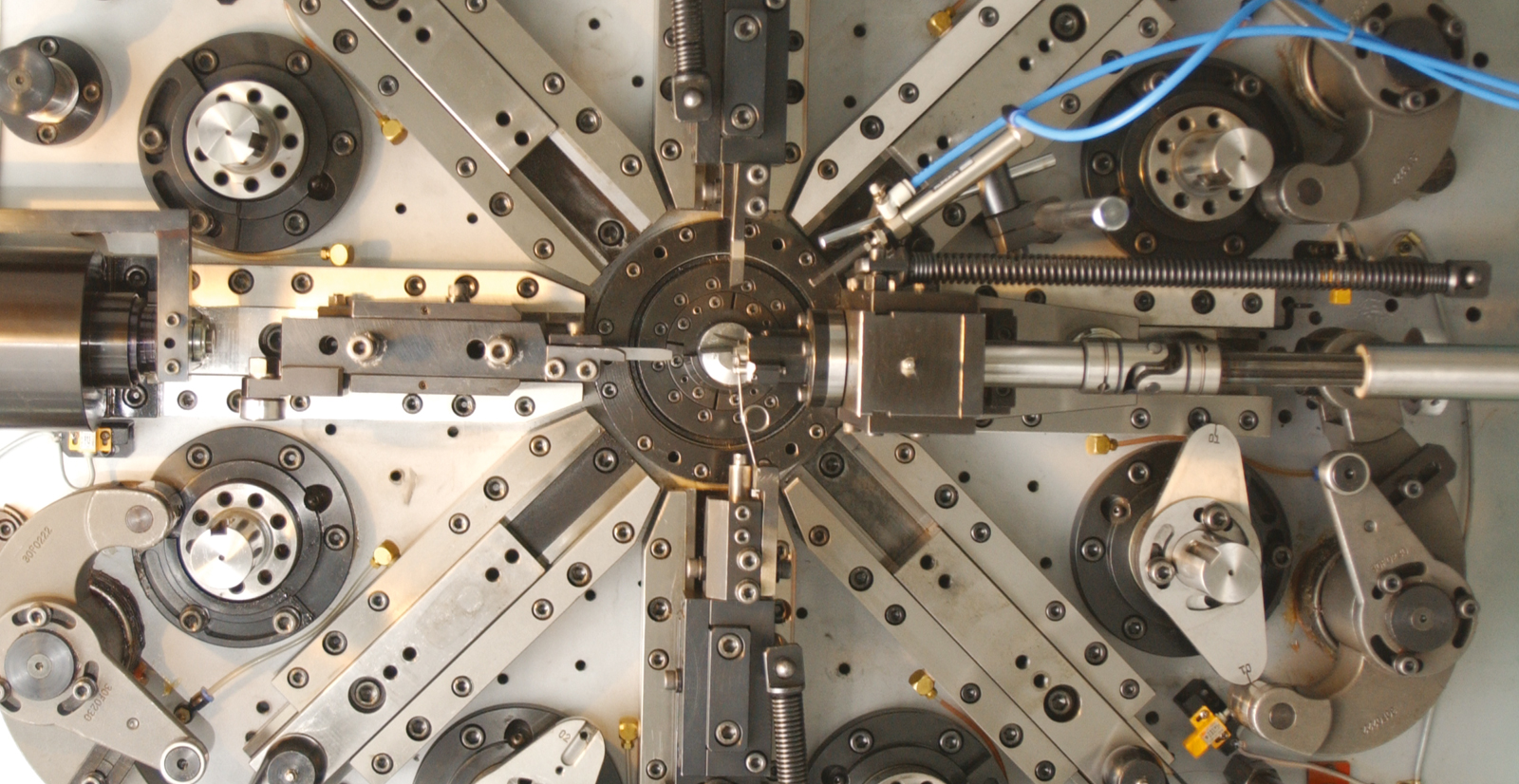

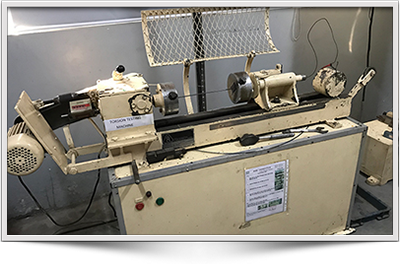

Germany, Taiwan, Korea & China

We have the latest machines for all spring making processes to achieve maximum accuracy, consistency, flexibility & productivity at high volumes. We have full range of CNC and Cam driven machines offering immense capacity. Our Automatic Grinding facilities are among the most advanced in the industry and employ point of grind air cooling to reduce heat generation and ensure consistent quality. We also have extensive range of online conveyerised heat treatment and short peening facilities. All manufacturing batch traceability as standard procedure.

Our CNC spring formers are 18 axis machines for torsion & tension springs and wireforms from wire dia 0.40 mm to 5.50 mm. End less variety of springs can be produced with automatic production, bulit in dimensional control through sensors and high speed operation.

Our CNC spring coilers are multi axis machines for compression springs from wire dia 0.10 mm to 9.00 mm. End less variety of springs can be produced with automatic production, dimensional control with length gage & 3 way sorter, rotating cutter fro burr free cutting & high speed operation.

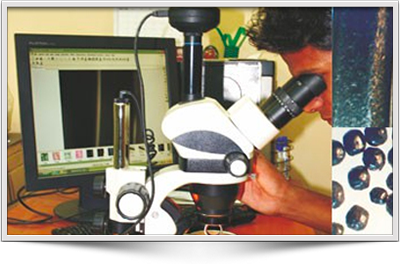

Our fully automated spiral springs production line is installed in technical collaboration with Korean Company “T&R”.This production line is Equipped with Camera monitoring & Call Back system to monitor the running machine and call back in case of any fault. All sensors are in place to have complete dimensional control.

The Electric conveyer furnace with automatic PID temperature cotrol helps in achieving high quality tempering & stress relieving. It has built in fault detection system with alarm.

The CNC Spring grinding machine for end grinding of springs has micro length controller for high accuracy & multiple plates for high production. End grinding can be done for springs with wire dia up to 12mm.

Quality System is approved to ISO/TS16949:2009

Our quality assurance procedures cover the entire development and manufacturing processes and use statistical tools to assure process stability and capability. We identify the common causes of variation in processes in order to keep them in satisfactory control.

Feel Free to Contact for Any Inquire at Anytime

Plot No-44, IMT Sector 68,

Plot No-44, IMT Sector 68,

Faridabad, Haryana 121005